PTFE TEFLON GASKETS AND SEALS

In the industrial sector, the durability and quality of materials are crucial for ensuring the longevity and efficiency of applications. Among the various materials used, Teflon (PTFE) gaskets stand out for their excellent chemical, thermal, and mechanical resistance properties. These specs make them indispensable components in numerous applications, providing reliable performance even under the most severe conditions.

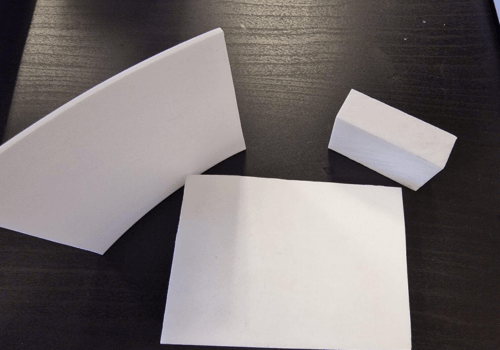

PTFE Gaskets Types And Shapes

PTFE gaskets come in various types and shapes:

- Custom PTFE gaskets

- Flat PTFE gaskets

- Radial PTFE gaskets

- Lip PTFE gaskets

- Spiral PTFE gaskets

- Envelope PTFE gaskets

- Oval PTFE gaskets

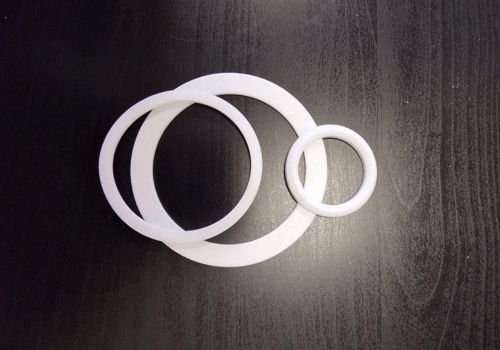

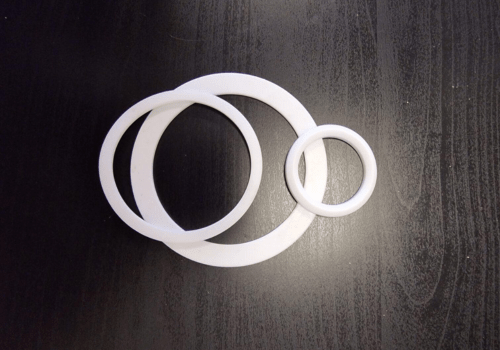

- Circular PTFE gaskets

- Sealing rings

- PTFE fittings gaskets

- O-rings

- Anti-extrusion rings

- Sealing rings for oil seals and covers

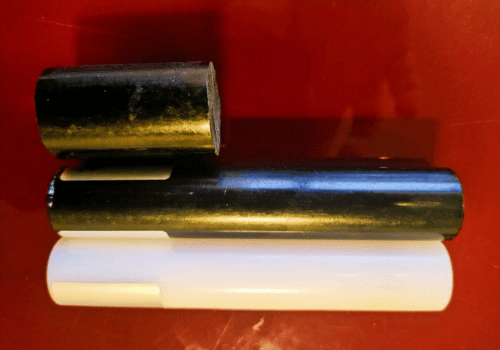

- PTFE V-ring cylinder gaskets

- X-rings

- Custom-made PTFE gaskets

Benefits of Teflon PTFE seals

Teflon PTFE seals offer numerous advantages due to their material properties. These benefits include exceptional chemical resistance, a wide operating temperature range, and superior food compatibility, making them ideal for various industrial and food-grade applications.

Production of Seals and Mechanical Components

Teflon PTFE sheets are used widely for producing gaskets, which are crucial for maintaining the tightness of machinery. These seals prevent leaks and resist chemical and thermal degradation, ensuring long-term reliable and safe operations.

Chemical equipment coatings

Teflon PTFE’s chemical resistance makes it an ideal coating for chemical equipment. This special coating protects the equipment from corrosive substances, extending the lifespan of machinery and reducing maintenance costs.

Operating temperature

Teflon PTFE seals can function across a broad temperature range, from -200°C to +260°C, without losing their properties. This thermal versatility makes them suitable for applications ranging from cryogenic to high-temperature conditions, providing a reliable solution for various operational needs.

Food compatibility

Teflon PTFE is non-toxic and approved for food contact according to European and international regulations such as EC 1935/2004, CE 10/2011, REACH, FDA and others. This food compatibility makes PTFE seals ideal for the food sector, where safety and non-contamination are paramount. Their chemical inertness and thermal resistance allow their use in food processing and packaging, ensuring maximum hygiene and safety.

Chemical resistance

Teflon PTFE is virtually inert to most chemical compounds, making it perfect for those applications requiring corrosion resistance. This exceptional chemical resistance allows PTFE seals to be used in aggressive environments where other materials could fail.

PTFE coating ensures protection from chemical agents, acids, and solvents, maintaining consistent performance over time.

Teflon PTFE seals provide significant advantages in chemical resistance, operating temperature, and food compatibility, making them an excellent choice for various industrial and food applications.

Applications of PTFE Seals

Chemical and Pharmaceutical industries

PTFE gaskets are widely used in the chemical and petrochemical industries due to their exceptional resistance to corrosive agents, such as concentrated sulphuric acid, and a wide range of aggressive chemicals. Their ability to withstand extreme conditions makes them indispensable for chemical reaction boilers, evaporators, heat exchangers, pipes, pumps, storage tanks, and valves. The thermal resistance and chemical compatibility of PTFE gaskets make them ideal for use in acid-base, high-temperature, and high-pressure environments typical of this industry.

Food and beverage industry

PTFE seals are used in the food industry, where safety and non-contamination are essential. Their non-toxicity and chemical resistance make them suitable for food processing equipment, beverage production, and food-delivery pipelines. Their ability to operate across a wide temperature range without altering their properties makes them compatible with various food production processes.

Plumbing and heating systems

PTFE gaskets are also employed in plumbing and heating systems due to their high mechanical resistance and effectiveness across a broad temperature range, from -200°C to 260°C, and at pressures up to 100 bar. However, note that they are not suitable for use with gas. These specs make them a reliable solution for ensuring the efficiency and safety of plumbing and heating systems in various operating conditions.

Pharmaceutical sector

In the pharmaceutical industry, PTFE seals are chosen for their purity, chemical resistance, and ability to perform under extreme temperature conditions. These qualities make them ideal in storage and delivery equipment, reactors, pump seals, and pharmaceutical machinery. Compliance with stringent regulations such as FDA and EC 1935/2004 ensures safety in applications involving contact with ingestible substances.

Types of PTFE Gaskets

1. Gaskets for flanges and fittings

Teflon PTFE gaskets are especially suited for flanges and fittings due to their chemical resistance and ability to adapt to joint imperfections. Expanded PTFE, which is 100% pure, is highly effective in these applications because it is very soft and can achieve a seal even with low tightening torques.

2. Glass fiber or carbon graphite filled gaskets

PTFE gaskets can be enhanced with additional components. Adding glass fiber to PTFE, in percentages from 5% to 40%, significantly improves wear and deformation resistance while maintaining the material’s original chemical and electrical properties. This type of gasket is ideal for applications requiring higher mechanical strength without compromising PTFE’s chemical inertness.

Conversely, PTFE filled with graphite, in percentages from 5% to 15%, is used to improve the coefficient of friction, making these gaskets particularly suitable for applications where low friction is needed. Graphite enhances resistance to deformation under permanent load and wear and improves thermal and electrical conductivity.

In summary, PTFE gaskets, whether in their standard form or enhanced with additives like glass fiber or graphite, offer several solutions to meet specific application needs. They combine chemical, thermal, and mechanical resistance in ways optimized for various operating conditions.

Trusted by Clients Worldwide

We have been sourcing virgin PTFE components from Felis S.r.l. for over a decade. The quality is consistently flawless, meeting our strict engineering standards. Their team’s technical expertise and timely deliveries have been crucial to keeping our production lines running smoothly.

Giovanni R., Industrial Engineer Milan, Italy

Felis S.r.l. stands out for their professionalism and precision. The PTFE and POMC C items we receive are exactly as specified, with excellent durability and performance. Their responsiveness and customer care make them a trusted partner for our business.

Laura P., Procurement Manager - Barcelona, Spain

From the first inquiry to the final delivery, Felis S.r.l. has provided exceptional service. Their virgin PTFE products have exceeded expectations in both quality and longevity. We highly recommend them to anyone looking for reliable and top-tier industrial components.

Markus K., Operations Director - Munich, Germany

Request Your PTFE Quote

Worldwide delivery and certified PTFE products.

PTFE TEFLON GASKETS AND SEALS

PTFE TEFLON GASKETS AND SEALS

PTFE gaskets come in various types and shapes:

- Custom PTFE gaskets

- Flat PTFE gaskets

- Radial PTFE gaskets

- Lip PTFE gaskets

- Spiral PTFE gaskets

- Envelope PTFE gaskets

- Oval PTFE gaskets

- Circular PTFE gaskets

- Sealing rings

- PTFE fittings gaskets

- O-rings

- Anti-extrusion rings

- Sealing rings for oil seals and covers

- PTFE V-ring cylinder gaskets

- X-rings

- Custom-made PTFE gaskets

purchase now

Purchase the articles of your interest directly

PTFE TEFLON GASKETS AND SEALS

In the industrial sector, the durability and quality of materials are crucial for ensuring the longevity and efficiency of applications. Among the various materials used, Teflon (PTFE) gaskets stand out for their excellent chemical, thermal, and mechanical resistance properties. These specs make them indispensable components in numerous applications, providing reliable performance even under the most severe conditions.

Benefits of Teflon PTFE seals

Teflon PTFE seals offer numerous advantages due to their material properties. These benefits include exceptional chemical resistance, a wide operating temperature range, and superior food compatibility, making them ideal for various industrial and food-grade applications.

Chemical resistance

Teflon PTFE is virtually inert to most chemical compounds, making it perfect for those applications requiring corrosion resistance. This exceptional chemical resistance allows PTFE seals to be used in aggressive environments where other materials could fail.

PTFE coating ensures protection from chemical agents, acids, and solvents, maintaining consistent performance over time.

Operating temperature

Teflon PTFE seals can function across a broad temperature range, from -200°C to +260°C, without losing their properties. This thermal versatility makes them suitable for applications ranging from cryogenic to high-temperature conditions, providing a reliable solution for various operational needs.

Food compatibility

Teflon PTFE is non-toxic and approved for food contact according to European and international regulations such as EC 1935/2004, CE 10/2011, REACH, FDA and others. This food compatibility makes PTFE seals ideal for the food sector, where safety and non-contamination are paramount. Their chemical inertness and thermal resistance allow their use in food processing and packaging, ensuring maximum hygiene and safety.

Teflon PTFE seals provide significant advantages in chemical resistance, operating temperature, and food compatibility, making them an excellent choice for various industrial and food applications.

Applications of PTFE seals

Chemical and petrochemical industry

PTFE gaskets are widely used in the chemical and petrochemical industries due to their exceptional resistance to corrosive agents, such as concentrated sulphuric acid, and a wide range of aggressive chemicals. Their ability to withstand extreme conditions makes them indispensable for chemical reaction boilers, evaporators, heat exchangers, pipes, pumps, storage tanks, and valves. The thermal resistance and chemical compatibility of PTFE gaskets make them ideal for use in acid-base, high-temperature, and high-pressure environments typical of this industry.

Pharmaceutical sector

In the pharmaceutical industry, PTFE seals are chosen for their purity, chemical resistance, and ability to perform under extreme temperature conditions. These qualities make them ideal in storage and delivery equipment, reactors, pump seals, and pharmaceutical machinery. Compliance with stringent regulations such as FDA and EC 1935/2004 ensures safety in applications involving contact with ingestible substances.

Food industry

PTFE seals are used in the food industry, where safety and non-contamination are essential. Their non-toxicity and chemical resistance make them suitable for food processing equipment, beverage production, and food-delivery pipelines. Their ability to operate across a wide temperature range without altering their properties makes them compatible with various food production processes.

Plumbing and heating systems

PTFE gaskets are also employed in plumbing and heating systems due to their high mechanical resistance and effectiveness across a broad temperature range, from -200°C to 260°C, and at pressures up to 100 bar. However, note that they are not suitable for use with gas. These specs make them a reliable solution for ensuring the efficiency and safety of plumbing and heating systems in various operating conditions.

Types of PTFE Gaskets

Gaskets for flanges and fittings

Teflon PTFE gaskets are especially suited for flanges and fittings due to their chemical resistance and ability to adapt to joint imperfections. Expanded PTFE, which is 100% pure, is highly effective in these applications because it is very soft and can achieve a seal even with low tightening torques.

Glass fibre or carbon graphite filled gaskets

PTFE gaskets can be enhanced with additional components. Adding glass fibre to PTFE, in percentages from 5% to 40%, significantly improves wear and deformation resistance while maintaining the material’s original chemical and electrical properties. This type of gasket is ideal for applications requiring higher mechanical strength without compromising PTFE’s chemical inertness.

Conversely, PTFE filled with graphite, in percentages from 5% to 15%, is used to improve the coefficient of friction, making these gaskets particularly suitable for applications where low friction is needed. Graphite enhances resistance to deformation under permanent load and wear and improves thermal and electrical conductivity.

In summary, PTFE gaskets, whether in their standard form or enhanced with additives like glass fibre or graphite, offer several solutions to meet specific application needs. They combine chemical, thermal, and mechanical resistance in ways optimized for various operating conditions.

Other products